News

Quality standard: CE Mark remains for construction products. (Published HVR June 2025)

After months of uncertainty, it is now official. The UK will continue to use the CE mark for construction products. Following BREXIT, the UK government introduced the UKCA mark with the intention of replacing the CE mark. However, since Brexit government policy has been to keep British standards in close alignment with European standards removing the need for a separate quality mark. This decision also removes the separate rules created for Northern Ireland as part of the Brexit agreement.

Through BSi the chimney and flue industry contributes to the development of European/British standards which underpin the CE mark. It is worth noting that the UK can modify European standards by creating a UK Annex to go with the standard. The UK Annex to BSEN15287, the key standard for the design and installation of flues, is currently being finalised. When published, hopefully later this year it will bring the regulations in the standard into line with UK building practices. The British Flue and Chimney Manufacturers Association (BFCMA) will publicise the publication of the Annex through its web site and social media posts.

The purpose of the CE mark is designed to give the user confidence that the product is fit for purpose. It is based on the achievement of exacting product standards, in standards like BSEN15287. Specifiers and installation should always look for the CE mark.

Commercial & Domestic Flues.

The design and installation of chimneys and flues in the residential sector are covered by Approved Document J. There is no such equivalent document in the commercial sector. To fill the gap the BFCMA has published a Commercial Flue Guide for commercial flues. The guide covers chimney principles, flue design & maintenance, flue height and the Clean Air Act. The guide gives a useful overview on the selection and installation of chimneys and flues in commercial applications.

Matching the flue.

The function of a chimney or flue is to safely discharge the products of combustion into the atmosphere. This however is not as straight forward as it may sound. Most chimneys operate under negative pressure, using the laws of thermal dynamics to transport the flue gases along the length of the chimney/flue to atmosphere. This requires a clear path to the top of the flue that also maintains the temperature of the flue gases above the dew point.

Chimneys and flues are required to discharge a variety of combustion gases. Different flue gases require different classes of flue. The chimney and flue standards provide for a user-readable classification system that designates the features of the flue components. The features covered include temperature and pressure rating, condensates, corrosion resistance and distance to combustibles. The label on stainless steel components showing the classification should always be checked before installing.

Product Testing

Product standards are validated on the basis of product testing. Chimney and flue components under rigorous testing to prove that they can meet the required performance and simulation software is used to confirm that they will function as specified.

System Flues.

Both flue components and system chimneys are covered by the CE mark. It should, however, be noted that a CE mark for a system chimney applies to the complete flue system, including add on components like rain caps. The use of components that have not been tested with the system chimney will invalidate the CE mark and change the classification of the flue to a custom flue, for which the installer is responsible.

BFCMA.

The BFCMA is the UK's only Trade Association representing the chimney and flue industry. It represents the majority of manufacturers and sole distributors in the UK.

The BFCMA works closely with Government, public bodies and other organisations to further the interest of the chimney & flue industry.

The BFCMA is a member of the Federation of Environmental Trade Associations (FETA) which is the low cost but high-profile UK trade body which represents the diverse interests of manufacturers, suppliers, installers and contractors within the building services sector.

The benefits of modern wood burning stoves

A Modern Approach (Published in Selfbuilder January 2025)

With the controversy over wood burning stoves, it is worth looking at the benefits of modern stoves. Combined with quality wood, modern stoves offer significant benefits that align with the objectives of reducing carbon emissions and improving air quality.

At the start of 2025 the Scottish Government changed the law on the use of bioenergy heating systems in new builds and amended the Scottish New Build Heat Standard (NBHS) to allow bioenergy systems, including wood burning stoves, to be installed in all new homes and in existing buildings that are being converted. The minister heralded it as a “common sense and progressive step”.

The Scottish Government now considers the combustion of biomass to produce net zero CO2 emissions at the point of use.

Wood fuel is a renewable resource that, when sourced sustainably, is a very a low carbon option for heating. The carbon dioxide released during combustion is offset by the carbon dioxide absorbed by trees during their growth, making wood fuel an extremely low CO2 energy source, with the biogenic carbon content being carbon-neutral. The sustainable nature of wood burning comes from the fact logs are generally the off cuts that come from pruning trees. Woodlands need to be managed to stay healthy and part of that management is pruning.

When used together, modern wood burning stoves and heat pumps can provide a comprehensive and flexible heating option and perhaps the most cost-effective solution to decarbonising domestic heat. Stoves can complement heat pumps by providing additional warmth during extremely cold periods.

With the pressure to reduce particle emissions, it is often overlooked that modern wood burning stoves burn wood more efficiently and cleanly than open fires and older stoves. The use of modern wood burning results in significantly lower levels of PM2.5 emissions.

When choosing a stove, it is worth checking out the independently verified Clear Skies web site. Clear Skies can help you identify stoves that produce fewer emissions, including those that are suitable for use in smoke control areas.

Secondary Heating is not regarded as essential in the SAP assessment, used to measure the energy efficiency of a house design. SAP focuses on primary central heating systems like heat pumps. However, this does not mean that a stove cannot be added to a house design. In many households secondary heating is an important part of the heating mix, especially in areas off the gas grid. In the early Autumn and late Spring, when it is not cold enough to justify turning on the central heating system a wood burning stove can be used to keep the whole house warm. As the operation of a stove is independent of the national grid it can be used in a power cut, providing welcome heat.

It is generally accepted that the warm glow of a fire creates a feeling of wellbeing. In addition to these psychological benefits wood burning stoves are a cost effective way to heat your home. During the cost of living crisis, when energy costs dramatically increased, the sales of modern wood burning stoves grew significantly.

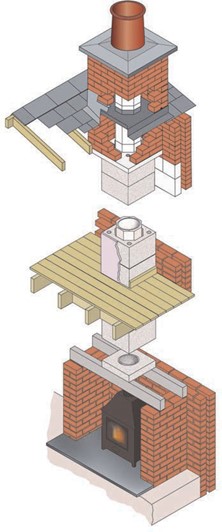

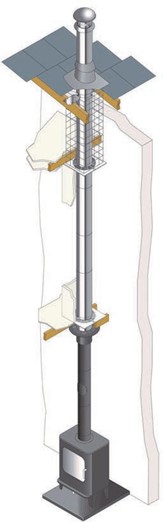

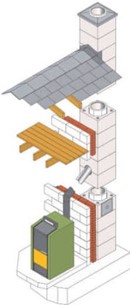

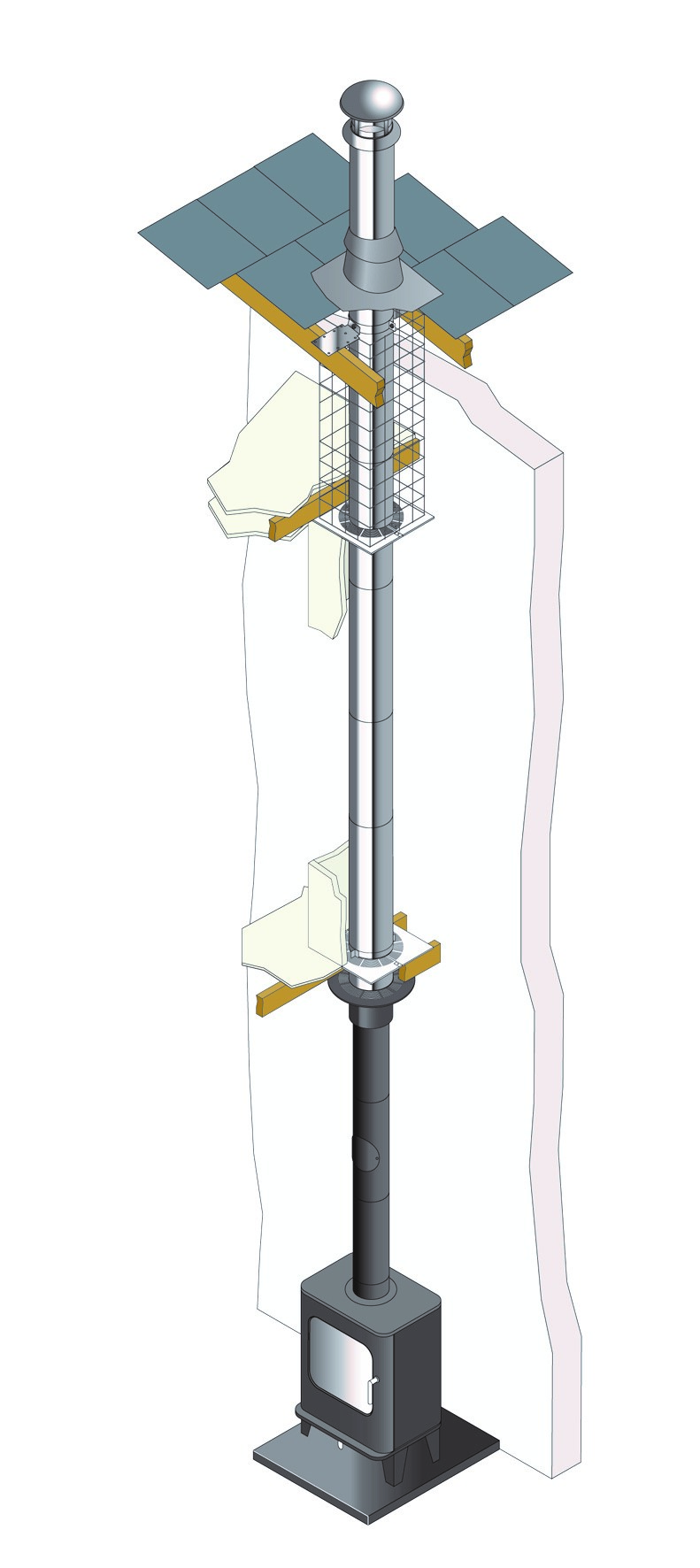

When designing your new home, it is necessary to think about the heating system, Stoves require a flue/chimney and to work effectively the route of the flue/chimney should be planned. The draw in the chimney/flue is even important with modern wood burning stoves. Most people’s desire is to make the flue/chimney as unobvious as possible inside the building. This needs to be balanced with need to keep the flue/chimney as straight as possible. The draw in flues/chimneys for rely on the pressure differential between inside and outside the building to release the products of combustion to the atmosphere. Bends in the flue/chimney can restrict the flow of the gases. Where bends are required to suit the design of the dwelling, the number of bends should be kept to a minimum and not exceed more than four. The angle of the bends should not be greater than 45° from the vertical. Horizontal lengths should be avoided.

Insulation is another key factor in keeping the flue gases above the dew point. Clay, concrete and pumice flue liners require insulation to be prepared and added on site. Stainless steel system chimneys are supplied with effective insulation. Double wall pumice chimney systems have an air gap between the walls of the inner and outer blocks. The air gap combined with the natural insulating properties of pumice provide effective insulation.

Stoves operate under what is referred to as negative pressure, so if you are installing a ventilation system it is important to keep the room in which the stove is to be installed under negative pressure.

Including a wood burning stove with a heat pump can provide a versatile hybrid heating system, able to deal with fluctuating temperature conditions. If you consider installing a stove remember the flue/chimney requirements and incorporate them into the house design.

The BFCMA is the UK’s only Trade Association representing the chimney and flue industry and works closely with Government, public bodies and other organisations to further the interest of the chimney & flue industry. It represents the majority of manufacturers and sole distributors in the industry. Dennis Milligan is President of the BFCMA.

What’s new in the chimney world?

New Standards (Published in HVR December, 2024)

The last year has seen a significant change in the publication of chimney standards. The log jam created by the European Commission is now starting to clear and the main standard for chimney design, commissioning and installation, BSEN15287, was published in October and the revised UK Annex is currently being worked on. More revised standards will now follow. In addition to defining how a product should be designed and installed product standards feed into Approved Document J. The BFCMA is hopeful that Document J will be updated in the near future. In the meantime, stay up to date with the BFCMA design and installation guides covering wood burning and multi fuel stoves, biomass appliances, gas appliances and commercial flues. The guides can be downloaded from the BFCMA web site.

Post Brexit, you might wonder why we are talking about the European Commission. Well, that is because the UK Government has decided to stay in alignment with the EU on product standards. The UK can, however, create a UK Annex to tailor the standard to UK practices.

The position on the UKCA mark continues to be uncertain with the previous government indicating that it would be 2025 at the earliest before an announcement would be made. In the meantime, the CE mark remains valid.

Ecodesign Stoves

The advent of Ecodesign stoves with their lower emissions has placed even more importance on the draw in the chimney/flue . One of the ways in which stove manufacturers have reduced emissions is to retain the products of combustion in the fire chamber for longer before releasing them into the flue. This can reduce the velocity a

nd temperature of the flue gases as they enter the flue. The draw of the chimney should be checked when installing the stove to ensure that the draw meets the stove manufacturer’s requirements.

Other ways of improving the performance of the chimney/flue include building the chimney as straight as possible and ensuring there is consistent insulation along the complete length of the flue. It is important that the temperature of the gases are maintained above the dew point as they travel up the flue/chimney. BFCMA members can advise on chimney design and installation. This includes using industry standard software to check that the flue design will create the required draw in the flue/chimney.

U Turn on Stoves

The decision of the Scottish Government to rethink the installation of stoves in new houses is to be welcomed.

The installation of bioenergy heating (biofuels and biomass) and peat heating systems is once again permitted in residential buildings. The Scottish Government stated that it “is akin to the position before the New Build

Heat Standard (NBHS) came into force on 1 April 2024, where no restrictions were placed on the use of these fuel types”.

The final decision on the future use of bioenergy fuels for both primary and secondary heating will be taken when the review of the NBHS and the associated technical guidance is concluded. (The review also includes an examination of the role of wood burning stoves in Scotland). The review is expected to support the use of bioenergy fuels for both primary and secondary heating but this cannot be taken for granted and continued lobbying of the Scottish Government will be required. The SIA spearheaded the campaign for a review of the NBHS, arguing that modern wood burning stoves are among the lowest carbon-emitting heating options available, significantly reducing carbon intensity compared to direct electric heating. The SIA also rightly raised concerns that a ban on wood burning stoves would leave many Scottish households, especially in rural areas, vulnerable to heat loss during power outages and exacerbate fuel poverty by limiting heating choices. The Minister described his decision as a “common sense and progressive step” which gives hope for the future.

The warm feeling of cost-efficiency (Published in Selfbuilder & Homemaker January 2024).

Dennis Milligan of the BFCMA explores the efficiency benefits of wood-burning stoves, how they work with heat pumps, and installation essentials.

Heat pumps work best when they are running at a constant temperature. A stove can complement a heat pump in cold weather by quickly boosting heat. Wood burning stoves can also provide comfortable heating for the whole house in autumn, and spring when it is not cold enough to turn on the central heating.

Heat security has also become an important consideration in severe winters. As a stove is independent of the electricity supply, it can keep the house warm when the electricity is off. Stoves are regarded as secondary heating and as such are not included in the government’s heating strategy.

Top on the list of reasons why people choose a wood burning stove is the visible warmth and comfort it creates. For many the stove is the focus of the room, with chairs and sofas arranged around it. Stove owners often talk about just how much they love the feel of the heat that comes from their stove. Another important reason, however, is financial. With the cost-of-living crisis and high energy prices being experienced, homeowners are also choosing wood burning as a cheaper alternative.

When choosing to have a wood burning stove, it is important to remember that a stove requires a chimney/flue to transport the 'products of combustion’ to the atmosphere. At the design stage, the route of the chimney/flue within the dwelling might not appear as one of the key considerations, but it is important to plan how the chimney/ flue will be incorporated in the house at this stage. The flue gases require a clear path to the top of the flue. A straight chimney/flue is always the best solution but where this is not possible, due to the construction of the dwelling, the number of bends should be kept to a minimum and not exceed more than four. The angle of the bends should be no greater than 45° from the vertical.

(The words chimney and flue are often used interchangeably. It is the inner tube that transports the flue gases. This is the flue. The chimney is the combined inner tube and the outer casing. A clear example is a brick chimney with a stainless steel liner).

Keeping the temperature of the flue gases above the dew point is really important to allow the flue gases to freely escape to the atmosphere. Clay, concrete and pumice liners require insulation to be prepared and added onsite. Stainless steel system flues are supplied with effective insulation. Double wall pumice chimney systems have an air gap between the walls of the inner and outer blocks. This air gap combined with the natural insulating properties of pumice provides effective insulation along the length of the chimney.

Installing a stove and flue is not a DIY job. It should only be undertaken by a competent person, and the work must be approved by Building Control. England and Wales operate competent schemes which allow the registered installer to self-certify the installation. HETAS and OFTEC are two of the main companies running such schemes. Scotland and N. Ireland need to have competent person schemes and Building Control must inspect the installation.

Once installed, it is important to regularly sweep the flue. The frequency of sweeping depends on the usage of the appliance. However, as a minimum the chimney should be swept at the start of the heating season. A build up in soot can impede the flow of the flue gases and increase the risk of a chimney fire. Remember that it is necessary to fit a carbon monoxide detector in the room where the stove is installed.

Burning dry wood not only gives more heat into the room, it also reduces soot deposits in the flue and the amount of particle emissions (PM). The Ready to Burn logo guarantees that the wood is dry enough to burn.

Concerns have been raised about particulate emissions (PM) from wood burning. The Environment Act sets out the emission limits that wood burning stoves must comply with. Many stoves already produce lower particulate levels than the Defra limits and that is where the independently verified scheme, Clear Skies, can be of assistance when purchasing a stove. The Clear Skies scheme identifies stoves that not only meet the emission limits required by Defra but also stoves that produce fewer emissions.

Wood burning is a low carbon form of heating. Logs are generally the off cuts that come from pruning trees. Woodlands need to be managed to stay healthy and part of that management is pruning. Interestingly, burning wood in a modern stove can produce less carbon than if it were left to decay on the woodland floor.

The BFCMA is the UK’s only Trade Association representing the chimney and flue industry and works closely with the Government, public bodies and other organisations to further the interest of the industry.

Dennis Milligan is president of the BFCMA

Interestingly, burning wood in a modern stove can produce less carbon than if it were left to decay on the woodland loor.

Choosing the right heating solution for your new home. (Published in Selfbuilder & Homemaker June 2023).

In this time of change it can be difficult to choose the best heating solution for your new home. Dennis Milligan of the BFCMA looks at the benefits of choosing a wood burning stove.

Heat pumps work best when they are running at a constant temperature. A stove can complement a heat pump in cold weather by quickly boosting heat. Wood burning stoves can also provide comfortable heating for the whole house in autumn and spring when it is not cold enough to turn on the central heating. Heat security has also become an important consideration in severe winter conditions. As a stove is independent of the electricity supply it can keep the house warm when the electricity is off. Stoves are regarded as secondary heating and as such are not included in the government’s heating strategy.

Top on the list of reasons why people choose a wood burning stove is the visible warmth and comfort created by the stove. For many the stove is the focus of the room, with chairs and sofas arranged around it. Stove owners often talk about just how much they love the feel of the heat that comes their stove. Another important reason is financial. With the cost-of-living crisis and high energy prices homeowners are also choosing wood burning as a cheaper alternative.

When choosing to have a wood burning stove it is important to remember that a stove requires a chimney/flue to transport the products of combustion to the atmosphere. At the design stage, the route of the chimney/flue within the dwelling might not appear as one of the key considerations but it is important to plan how the chimney/flue will be incorporated in the house at this stage. The flue gases require a clear path to the top of the flue. A straight chimney/flue is always the best solution but where this is not possible, due the construction of the dwelling, the number of bends should be kept to a minimum and not exceed more than four. The angle of the bends should be no greater than 45° from the vertical. (The words chimney and flue are often used interchangeably. It is the inner tube that transports the flue gases. This is the flue. The chimney is the combined inner tube and the outer casing. A clear example is a brick chimney with a stainless steel liner).

Keeping the temperature of the flue gases above the dew point is really important to allow the flue gases to freely escape to the atmosphere. Clay, concrete and pumice liners require insulation to be prepared and added on site. Stainless steel system flues are supplied with effective insulation. Double wall pumice chimney systems have an air gap between the walls of the inner and outer blocks. This air gap combined with the natural insulating properties of pumice provide effective insulation along the length of the chimney.

Installing a stove and flue is not a DIY job. It should only be undertaken by a competent person and the work must be approved by Building Control. England and Wales operate competent schemes which allow the registered installer to self-certify the installation. HETAS and OFTEC are two of main companies running such schemes. Scotland and N. Ireland do not have competent person schemes and Building Control must inspect the installation.

Once installed it is important to regularly sweep the flue. The frequency of sweeping depends on the usage of the appliance. However, as a minimum the chimney should be swept at the start of the heating season. A build up in soot can impede the flow of the flue gases and increase the risk of a chimney fire. Remember that it is necessary to fit a carbon monoxide detector in the room where the stove is installed.

Burning dry wood not only gives more heat into the room, it also reduces soot deposits in the flue and amount of particle emissions (PM). The Ready to burn logo guarantees that the wood is dry enough to burn.

Concerns have been raised about particulate emissions (PM) from wood burning. The Environment Act sets out the emission limits that wood burning stoves must comply with. Many stoves already produce lower particulate levels than the Defra limits and that is where the independently verified scheme, Clear Skies, can be of assistance when purchasing a stove. The Clear Skies scheme identifies stoves that not only meet the emission limits required by Defra but also stoves that produce fewer emissions.

Wood burning is a low carbon form of heating. Logs are generally the off cuts that come from pruning trees. Woodlands need to be managed to stay healthy and part of that management is pruning. Interestingly, burning wood in a modern stove can produce less carbon than if it was left to decay on the woodland floor.

The BFCMA is the UK’s only Trade Association representing the chimney and flue industry and works closely with Government, public bodies and other organisations to further the interest of the chimney & flue industry. It represents the majority of manufacturers and sole distributors in the industry.

High standards - a chimney and flue update

At long last the log jam for chimney product and installation standards is starting to be cleared. Dennis Milligan, president of the British Flue & Chimney Manufacturers Association (BFCMA), looks at the latest requirements

Chimney/flue requirements

While the design and installation of chimneys and fluesin the residential sector are covered by Approved Document J. there is no equivalent document in the commercial sector.To provide much needed guidance the BFCMA has published a Commercial Flue Guide.The guide covers chimney principles, regulations, chimney and flue design, chimney/flue height and the Clean Air Act.The aim of this guide is to provide a clearer understanding of how chimneys and flues should be selected and installed in commercial applications.

The CEmark and the planned UKCA mark(UK Conformity Assessed) are your guarantee that the product meets the prevailing product standards. After a number of false dawns, the UKCA mark is due to be implemented in 2025. The CE/UKCA mark is based on the achievement of exacting product standards, that have been developed to give the user confidence that the product is fit for purpose. Specifiers and installers should always look for the CE/UKCA mark. TheCE/UKCA mark applies to both flue components and to system chimneys.The CE/ UKCA mark for a system chimney applies to the complete flue system, including add components like rain caps. The use or components that have not been tested withthe flue invalidates the CE/UKCA mark and turns the flueinto a custom chimney. Different types of flue will be required to safely handle the different gases that need to be discharged. A key feature of thechimney and flue standards is a user-readable classification system that designates the features of the flue components. The features covered include temperature and pressure rating. fire. condensate. corrosion resistance and distance to combustibles. With stainless steelcomponents a label showing the classificationmust go with each flue component, so lhat It's specification can be easily verified.

Chimney/flue design

The purpose of a chimney or flue is to discharge the products of combustion safely to lhe atmosphere. Most chimneys operate under negative pressure, relying on naturaldraft to transport the flue gases to the atmosphere. This requires a clear path to the top of the flue. A straight chimney/flue is always the best solution but where this is not possible, due the construction of the dwelling, the number of bends should be kept to a minimum and not exceed more than four.The angle of the bends should be no greater than 45° from the vertical, with the exception that 90° factory made steelbends or tees may be treated as being equal to two 45' bends.

The chimney/flue must also maintain the temperature of the gases above the dew point. Good chimney/flue design requires consistent Insulation along the complete length of the flue. Clay, concrete and pumice liners require insulation lo be prepared and added on site. Stainless steel system chimneys are supplied with effective Insulation. Double wall pumice chimney systems have an air gap between the walls of the Inner and outer blocks. The air gap combined with the natural insulating properties of pumice provide effective insulation. The appliance and the chimney/flue have to work together for the appliance to perform correctly. The velocity and temperature of the gases entering the flue can be Important elements in how well the chimney/flue will operate. Advances in wood burning stove technology. designed to reduce emissions have highlighted the need for sufficient draw In the chimney/flue. The BFCMA is the UK'sonly Trade Association representing the chimney and flue industry and worksclosely with government, public bodies and other organisations to further the interest of the chimney & flue industry. It represents the majority of manufacturers

The hybrid role for wood burning stoves. (Published in the Architects Datafile September 2023).

The future of home heating is largely focused on the use of heat pumps. However other heating systems can be used in a complementary and sustainable way. One such system is wood burning stoves. Although not physically connected heat pumps and stoves can be viewed as an effective hybrid system. Dennis Milligan, president of the BFCMA, looks at the benefits of using a wood burning stoves with heat pumps.

Regarded as secondary heating and therefore not in the mix for primary, central heating systems wood burning stoves can provide quick and effective booster heating during a cold snap. (Heat pumps work best in a steady state and cannot respond quickly to temperature changes). In the autumn and spring when it is not cold enough to justify putting on the central heating system wood burning stoves can provide comfortable heating for the whole house. As stoves operate independently from the electric supply homeowners with stoves are also able to continue heating their homes in a power cut. These benefits come on top of the ecstatic benefits homeowners enjoy from having a wood burning stove.

Wood burning stoves require a flue/chimney. The purpose of the chimney or flue is to discharge the products of combustion safely to the atmosphere. To work effectively the stove and the flue/chimney should be considered as a complete system. The routing of the chimney/flue should be planned at the design stage. Most wood burning stoves and chimneys operate under negative pressure, relying on natural draft to transport the flue gases to the atmosphere. This requires a clear path to the top of the flue. A straight chimney/flue is always the best solution but where this is not possible, to suit the design of the dwelling, the number of bends should be kept to a minimum and not exceed more than four. The angle of the bends should not be greater than 45° from the vertical, with the exception that 90° factory made steel bends or tees may be treated as being equal to two 45° bends. Horizontal lengths should be avoided.

The draw in the chimney/flue is even more important with the advent of Ecodesign stoves. One of the ways in which stove manufacturers have reduced emissions is to retain the products of combustion in the fire chamber for longer before releasing them into the flue. This needs to be borne in mind when designing a chimney/flue as holding the flue gases longer in the fire chamber can reduce the velocity and temperature of the flue gases as they enter the flue. It is always advisable to check the stove manufacturer’s recommendations and that of the flue/chimney company. BFCMA members can advise on chimney design and installation. This includes using industry standard software to check that the flue design will create the required draw in the flue/chimney.

It is also important that the temperature of the gases are maintained above the dew point as they travel up the flue/chimney. Good flue/chimney design requires consistent insulation along the complete length of the flue. Clay, concrete and pumice flue liners require insulation to be prepared and added on site. Stainless steel system chimneys are supplied with effective insulation. Double wall pumice chimney systems have an air gap between the walls of the inner and outer blocks. The air gap combined with the natural insulating properties of pumice provide effective insulation.

The lower emission limits for wood burning in Defra’s Environment Act could make it difficult for new open fires to meet the lower emission limits. It has been common practice to include 200mm flues and a standard fire opening in detached houses, leaving the choice of appliance to the homeowner. Wood burning stoves require a smaller flue diameter, typically 150mm. Installing a smaller diameter flue also has the benefit of substantially reducing the air loss in SAP. SAP does not include secondary heating in the Notional Building. However, this does not mean that a stove with a flue/chimney cannot be added to the house design. Using the smaller flue diameter will significantly reduce the air loss calculation.

There have been concerns about particulate emissions (PM) from wood burning. The Environment Act sets significantly lower emission limits for wood burning stoves than in the past. Many stoves already produce lower particulate levels than the Defra limits. The independently verified scheme, Clear Skies, identifies stoves that not only meet the emission limits required by Defra but also stoves that produce fewer emissions.

The sustainable nature of wood burning comes from the fact logs are generally the off cuts that come from pruning trees. Woodlands need to be managed to stay healthy and part of that management is pruning. Interestingly, burning wood in a modern stove will produce less carbon than if it was left to decay on the woodland floor.

Including a wood burning stove with a heat pump adds value to a house. If you consider doing so do remember the flue/chimney requirements and incorporate them into the house design.

The BFCMA is the UK’s only Trade Association representing the chimney and flue industry and works closely with Government, public bodies and other organisations to further the interest of the chimney & flue industry. It represents the majority of manufacturers and sole distributors in the industry.

Cutting Pollution from Household Burning

The British Flue and Chimney manufacturers (BFCMA) supports the Government action to cut pollution from household burning, announced on 21st February, 2020.

Burning wet wood makes no sense on any level. Freshly cut wood consists of between 60% and 80% water, so burning it before drying is like trying to burn water, producing steam and smoke but little heat.

Burning wood that has a moisture content below 20% in an open fire or stove will dramatically reduce the particulate emissions compared to wet wood. The introduction of the Woodsure Ready to Burn scheme will help consumers identify wood that has the appropriate moisture content. For those people who have access to freshly cut wood should leave logs to dry naturally. This is known as seasoning and can take between 1 and 2 years depending on the species.

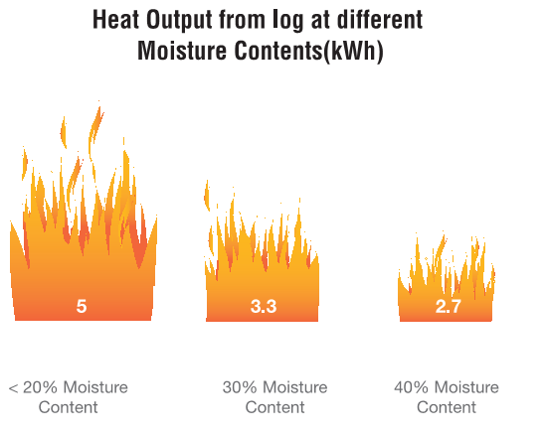

The higher price of pre-dried wood can be substantially offset by greater heat produced by burning dry wood. Fewer logs are required to produce the same level of heat as illustrated in the attached infographic.

Sulphur is not only bad for the environment it can also corrode appliances and stainless steel flues. Banning household coal and capping the volume of sulphur at 2% in smokeless fuels is good news for the health of appliances and flues.

Defra does not plan to ban open fires or stoves. Instead Defra believes that banning wet wood and household coal will enable them to meet their emission reduction targets.

For further details contact Dennis Milligan at dennis@denmil.com

Document J reflects the Latest Guidance on the Installation of Chimneys and Flues

Document J now recognises the alternative installation methods introduced in the latest edition of the European standard for the installation of flues and chimneys. An acknowledgement of the updated standard (BSEN 15287-1) has been posted in the Frequently Asked Questions and Answers section of Document J. This removes any grey issues in working to the updated European standard.

The UK annex to BSEN 15287-1, the installation standard for flues and chimneys was revised in 2013. The updated standard contains a number of significant changes in installation practice for wood burning and multi fuel stoves. Stainless steel twin wall flue can now be used as connecting flue pipe, connecting directly to appliance. This can significantly reduce the required distance to combustibles. Under certain circumstances the length of horizontal flue through a wall can be increased from 150mm to 450mm, simplifying the connection through the wall to an external flue. The new annex also suggests alternative ways to facilitate the visual inspection of enclosed stainless steel flues in voids, as required by Document J.

The BFCMA guide, entitled General Guidance on the Selection and Installation of Flues and Chimneys for Wood Burning and Multi Fuel Appliances gives clear guidance on how to install a flue in accordance with the new standard. The guide can be downloaded from the BFCMA web site.

For further details contact Dennis Milligan at dennis@denmil.com

BFCMA creates new web site and guidance on chimneys for wood burning appliances.

The growing interest in the carbon saving potential of wood burning stoves has led to a corresponding growth in the number of flue and chimney installations for wood burning appliances. Increasingly heating engineers are seeking to add the installation of wood burning stoves as one of their competences.

To help meet this need for information the BFCMA has created a new web site (www.bfcma.co.uk) with a downloadable document giving guidance on the selection and installation on flues and chimneys.

The web site has an easy to understand overview of the different types of chimneys and flues available with links to individual BFCMA members’ web sites for a more detailed explanation of the products and how they should be used. There are also standard installations drawings showing how the different types of flues and chimneys should be installed with wood burning appliances. The regulations for wood burning and solid fuel are different to those for gas and oil appliances; as are some of the flues that can be used. So it is important that the appropriate flue or chimney is installed with an appliance.

The web site can be used as a reference site for installers and specifiers as it contains an up-to-date listing of latest flue and chimney standards. Guidance is also given on the new standard for clay chimney liners. The standard was revised in 2012 into two parts to cover liners both non-condensing and condensing appliances. People can become confused by the CE designation for stainless steel flues so there is a clear explanation of the coding system used to specify the different classes of flue.

The web site and the guide have been developed to give installers and people thinking of buying a wood burning appliance a better understanding of what is involved in correctly flueing a wood burning stove. There are sections on the design, installation and maintenance of flues and chimneys. The guidance given is line with the training given to installers by HETAS.

This is the first stage in a series of initiatives designed to provide clear information on the installation and use of chimneys and flues. Already planned for 2013 are guidance on the flueing of pellet boilers and an overview of the new UK annex to the installation standard for chimneys (BSEN15287). The publication of the guidance on the flueing of pellet boilers is timed to meet the anticipated increase in demand for pellet boilers through the Green Deal initiative. By simply registering on the BFCMA web site people can be sure of receiving these documents when they are published.

The BFCMA is the British flue and chimney manufacturers association. The Association represents the main manufacturers and sole importers of chimneys and flues in the UK. The BFCMA works closely with government departments and other organisations to provide efficient and safe chimney solutions.

For further details contact Dennis Milligan at dennis@denmil.com